- Home

- Products

- Horizontal Flow Wrapper

- KCIV-388 Vertical packaging machine

KCIV-388 Vertical packaging machine

The KCIV-388 vertical packaging machine is used to weigh products, fill the packaging bag, then seal the bag. It is ideal for wrapping granular, block, and strip shaped products, including food. The feed system is available as a chain bucket type, a vibrating type and a rotary type.

Samples

Bag types

Pillow bag

Pillow bag Pillow bag with euro hole

Pillow bag with euro hole Pillow bag with round hole

Pillow bag with round hole Stick seal bag

Stick seal bag Linking bag

Linking bag 3 side sealed bag

3 side sealed bag 4 side sealed bag

4 side sealed bag Gusset bag

Gusset bag Triangle bag

Triangle bag

Specification

| Model | KCIV-388 |

| Film Width | Max.320MM |

| Bag Length | 50-200MM |

| Bag Width | 50-150MM |

| Film Roll Diameter | Max.300MM |

| Packaging Rate | 35-70Bag/Min |

| Power | 220V 50/60HZ 2.2KW |

| Packing Film Material | OPP/CPP,OPP/P, BOPP/VMPET/PE etc |

| Machine Size(L*W*H) | 970*680*1950MM |

| Machine Quality | About 300KG |

Details

Features

- Adjustable bag former to accommodate various product dimensions.

- Top film roll holder is adjustable for the easy centering of film and the braking system can stop the machine automatically when film runs out.

- The feeding conveyor features an adjustable width for various product dimensions.

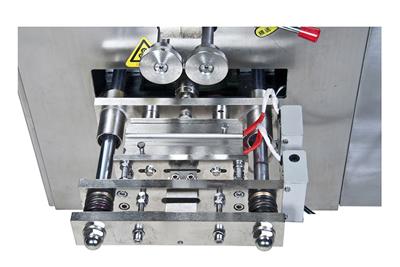

- Rotating jaw sealing head with maximum flexibility.

- Dual fin seal wheels.

- Safety covers to prevent operator access to moving parts.

- Easy to use touch screen controller.

- Independent temperature controllers for fin and end seals.

Options

- 304 stainless steel can be used for equipment parts, making it suitable for the food or medicine industry where hygiene standards are higher

- The end sealing can be completed with a box motion head or the rotary jaw head.

- Hot stamp printing for date codes

- Gas flush device for modified atmosphere packaging

- Extended feeding conveyor

- Auto feeding system

- Additional reel holder

- Gusseting device

Foshan Kincon Packaging Machinery is a dependable manufacturer of high-quality packaging machines. We offer high-performance horizontal fill and seal packaging machines, vertical form fill and seal packing machines, counting and weighing systems, and complete automated packing lines.

Inquiry

Foshan Kincon Packaging Machinery Co.,Ltd.

Address: NO.12, Shishan Road, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Contact: Ms. Kitty